(Click on thumbnail to enlarge)

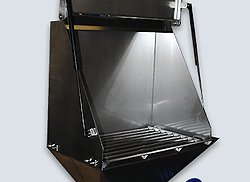

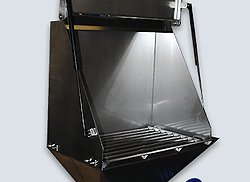

(Click on thumbnail to enlarge)Fabricated Stainless Steel Minor Ingredient Dump Station for an Industrial Conveying Equipment Manufacturer

(Click on thumbnail to enlarge)

(Click on thumbnail to enlarge)At ADM Custom Metal Fabrication, we built the minor ingredient dump station highlighted here for a customer in the industrial conveying equipment industry. Having the right equipment in our shop, and a skilled, detail-oriented workforce enabled us to plan, execute, test, and inspect this assembly within a four week timeframe.

Featuring dimensions of 30" in length x 24" in depth x 40" in height, we constructed this dump station from T316 stainless steel materials, including 11 gage sheet, ½" thick round stock, and ¼" and 3/8" plate. Primary operations involved saw cutting, laser cutting, forming, and welding. By using a stud welding we ensured that the fasteners were strongly bonded to a flat, clean surface, leaving no risk of material entrapment. We finished the workpiece with deburring, sanding, and grinding to achieve smooth surfaces and clean edges, and then polished it to a #4 finish to ensure the surface was completely defect-free.

Constructed and assembled to within ± 0.015" tolerances, we conducted multiple inspections at all critical stages of production to verify that we satisfied the requirements of the customer specification. This dump station allows the minor ingredients to be dispensed with precise control, accuracy, and repeatability.

If you would like more information about this project, or the processes we used to produce it, contact us today.

Fabricated Stainless Steel Minor Ingredient Dump Station Project Highlights:

- Product Name

- Minor Ingredient Dump Station

- Capabilities Applied/Processes

-

- Primary:

Laser Cutting

Saw Cutting

Forming

Welding

Stud-Welding - Secondary:

Time Saver

Sanding

Polishing

Assembly

- Primary:

- Equipment Used to Manufacture Part

- Amada Laser Cutter

Steel Master Wet Style 37" Belt Sander

130 Ton Trumpf Press Brake

TIG Welder

Hand-Held Grinder/Sander

Polishers

Stud Welder

- Overall Part Dimensions

- Length: 30"

Depth: 24"

Height: 40"

- Tightest Tolerances

- ± 0.015"

- Material Used

- 11 GA T316 Stainless Steel - #4 Polished Sheet

½” Thick T316 Stainless Steel Round Stock

¼” & ⅜” Thick T316 Stainless Steel Plate

- Material Finish

- #4 Polished Finish

- Additional Facts

- Assembly was done for customer approval

- In Process Testing/Inspection Performed

- Full Assembly Inspection

Dimensional Inspection, Visual Inspection

- Industry for Use

- Industrial Conveying Equipment Manufacturer

- Volume

- 1 Unit

- Delivery/Turnaround Time

- 4 Weeks

- Delivery Location

- New Jersey

- Standards Met

- Customer Specifications, CAD Drawing

OSHA Requirements

Printable Page

Printable Page Email This Page

Email This Page