(Click on thumbnail to enlarge)

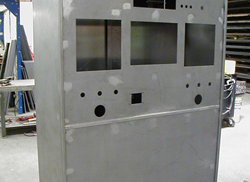

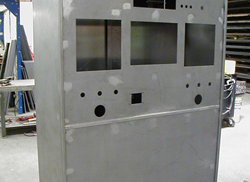

(Click on thumbnail to enlarge)Fabrication of a Steel Electrical Control Enclosure for an Industrial Equipment Manufacturer

(Click on thumbnail to enlarge)

(Click on thumbnail to enlarge)In the project highlighted here, ADM Custom Metal Fabrication was contracted to fabricate a custom electrical enclosure for an industrial equipment manufacturer. Utilizing 12 gauge cold rolled steel, a number of precision processes were performed to create the structure including punching, forming, welding and stud welding. This enclosure had openings in the front and rear, with the challenge to weld the cabinet consistently square so the front hinged doors would open properly and the removable horizontal rear panels would be equally spaced within their openings. This was accomplished as requested, meeting the tightest tolerance ± 0.015”. Overall dimensions of the completed enclosure were 72” in length, 24” in width, and a height of 78”. The unit was given a protective powder coating finish in gray, and comprehensively tested and inspected.

Equipment employed during fabrication included the a Trumpf punch, Steel Master wet style 37” belt sander, our 130 ton Trumpf press brake, MIG welder, and hand held grinder and sander. All construction took place at our state-of-the-art full service shop, upholding customer specifications as outlined in the furnished 2D CAD drawings. 7 enclosures were produced and delivered for this project, within a turnaround time of 5 weeks.

For more details about this custom steel electrical enclosure fabrication or the other metal manufacturing abilities available please see the table below or contact us directly.

Fabricated Steel Electrical Enclosure Project Highlights:

- Product Name

- Electrical Control Enclosure

- Capabilities Applied/Processes

-

-

Primary:

Punching

Forming

Welding

Stud-Welding - Secondary:

Powder Coating

-

Primary:

- Product Description

- Steel electrical control enclosure

- Equipment Used to Manufacture Part

- Trumpf Punch

Steel Master Wet Style 37” Belt Sander

130 Ton Trumpf Press Brake

MIG Welder

Hand-Held Grinder/Sander

- Overall Part Dimensions

- Length: 72”

Depth: 24”

Height: 78”

- Tightest Tolerances

- ± 0.015”

- Material Used

- 12 GA CRS (Cold Rolled Steel)

- Material Finish

- Powder Coat - Gray

- Additional Facts

- Hinged doors as shown accompanied by removable horizontal rear panels

- In Process Testing/Inspection Performed

- Full Assembly Inspection

Dimensional Inspection

Visual Inspection

- Industries Served

- Industrial Equipment Manufacturer

- Volume

- 7 Enclosures

- Delivery/Turnaround Time

- 5 Weeks

- Delivery Location

- New Jersey

- Standards Met

- Customer Specifications, 2D CAD Drawing

OSHA Requirements

Printable Page

Printable Page Email This Page

Email This Page